A Global Manufacturer

Manufacturing

Chemicals

Year

2026

Stack

Axium, Siemens Teamcenter

Unlock High-Performing PLM with AI

A global manufacturer with hundreds of configurable machines as products relies on SAP R/3 to manage product lifecycle data, but their legacy PLM system had become a bottleneck to innovation.

Modern Manufacturing demands more visibility, flexibility, and better access to advanced analytics to ensure the company stays competitive in a global economy. This requires seamless integration across systems and rapid configuration updates. Our client’s legacy Product Lifecycle Management (PLM) system was slowing down innovation and needed to be replaced.

For this purpose, our client decided to switch to Siemens Teamcenter. Partnering with MobiLab, they leveraged AI and Microsoft Azure to significantly accelerate the process, saving crucial engineering resources while ensuring that decades of expert knowledge embedded in the legacy system would be preserved in the modern platform.

⸻ STARTING POINT

Trapped in SAP Legacy Systems

Our client decided to adopt Model-Based Systems Engineering (MBSE), as the 25-year-old legacy landscape no longer supported modern workflows and digitalization goals. However, SAP’s ecosystem couldn’t fully address the evolving requirements. A new system was needed that meets the demands while preserving PLM knowledge, spanning hundreds of complex machines, without losing critical logic.

However, the migration process was highly complex and resource-intensive. Each machine represented decades of Subject Matter Experts’ (SMEs) experience and logic, stored as constraint rules, defined characteristics, and configuration procedures, deeply embedded within SAP using a proprietary language. Recreating all configuration logic manually would have consumed enormous time, budget, and engineering resources while introducing significant opportunity costs.

A manual pilot migration of a single machine’s PLM data to a modern system took the client six months. At that pace, migrating all machines would have tied up engineering resources for 10 years, leaving no capacity for innovation.

The core bottleneck was how knowledge had been stored in SAP through years of custom configurations per machine. As SMEs left or retired, much of this critical knowledge was at risk of disappearing, turning delay into a strategic threat.

A manual translation of this logic was not an option, the client needed a scalable, automated migration approach to accelerate the process while retaining existing knowledge.

While modern data architecture principles had been introduced, they were not yet consistently applied in the sustainability domain. Reusable data products, defined service levels for data quality, and value-driven governance cycles were still missing, limiting the ability to scale sustainability use cases efficiently.

⸻ SOLUTION

Accelerating Brownfield Migrations

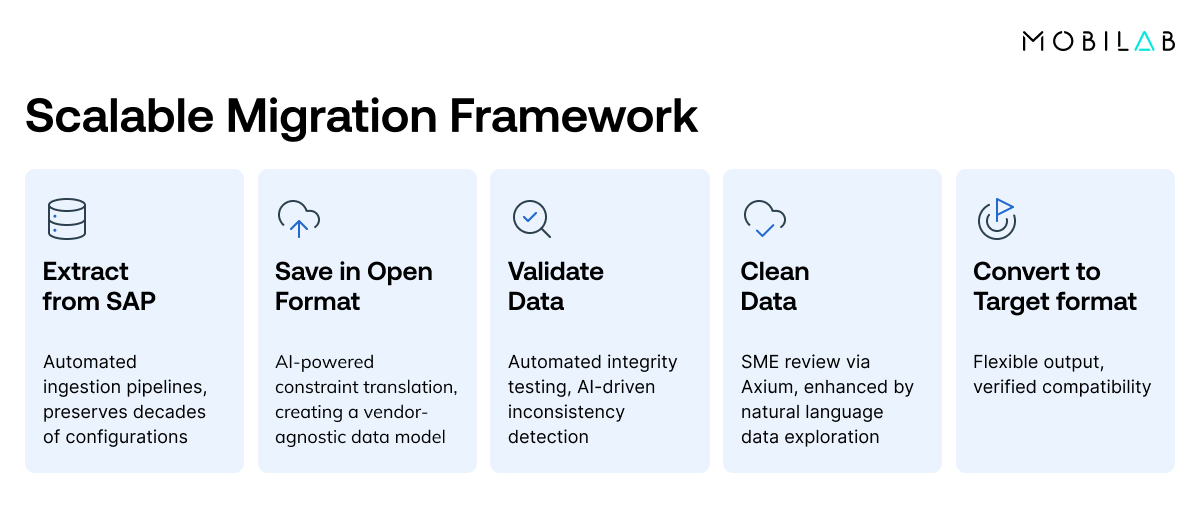

MobiLab built an AI-driven framework to extract, translate, and validate expert knowledge at scale.

Starting with high-priority machines, we combined manual baselines with LLMs to automate repetitive logic and continuously refined the pipeline through testing and feedback loops.

Central to this framework is Axium, MobiLab’s AI-driven platform that can accelerate complex brownfield system migration. Axium combines intelligent automation with a powerful visual interface, allowing SMEs to review, refine, and approve results efficiently.

Designed for streamlining data-heavy workflows, Axium leverages AI at its core to deliver reliability, scalability, and continuous learning.

⸻ Business Impact

A New Era in PLM Migration

The new AI-augmented pipeline reduced manual effort at every stage and dramatically accelerated the migration process. MobiLab built a system where AI wasn’t a side tool but a key actor in the migration.

The new AI-augmented pipeline reduced manual effort at every stage and dramatically accelerated the migration process. MobiLab built a system where AI wasn’t a side tool but a key actor in the migration.

85% faster migration:

Reduced per-machine processing time from 6 months to just a few hours, and overall timeline from 10 years to 18 months.

70% less SME reliance:

Experts can focus only on final validation, not manual translation.

Reusable logic and automation:

Prompts, rules, and quality metrics scaled across machines.

AI-continuous learning built-in:

With AI, the migration process improved with each iteration.

Clean, structured, ready-to-use data:

Legacy knowledge became searchable, comparable, and integration-ready.

AI in three roles:

As translator, reviewer, and assistant, AI helped automate tasks, validate results, and guide decisions.

Future-Ready Operations

This project was more than just a migration; it was a strategic shift. MobiLab built a future-ready foundation that transforms how product knowledge is managed, scaled, and reused.

A new outlook:

1. Agnostic, source-neutral structured data

Decoupled from legacy formats, data is now source-neutral and ready for use in Axium, Cameo, Siemens Teamcenter, and more.

2. From maintenance to innovation

SMEs can now focus on refinement and improvement, skipping tedious manual data preparation and cleaning tasks.

3. Liberated expert knowledge

Product knowledge is no longer trapped in legacy tools or individual heads. It’s structured, searchable, and reusable.

4. Governed AI by design

AI integration is customizable and governed. The usage level, validation steps, and logic rules are all adjustable based on the client’s needs.

By embedding intelligence into both the process and the data, we enabled our client to accelerate migration with greater control, enhanced visibility, and growing confidence.

Start small and scale.

Axium is designed future-proof, for all businesses to organize their knowledge and leverage the power of data and actionable business insights.

Let's go forward. Together.

Every business is unique. Let us show you how Axium can accelerate your data journey. Get in touch with us today!